Polymer Extrusion

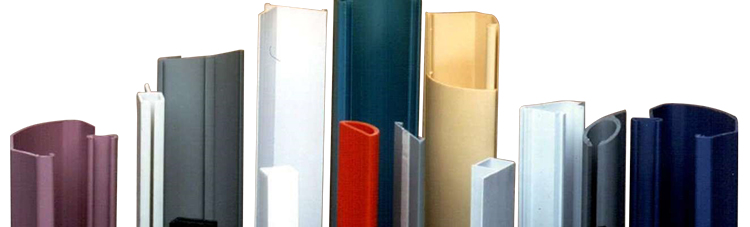

With the MES extrusion processes you can chose from a large and diversified range of polymers. Molded Extruded Specialties possess the capability and knowledge to produce a limitless selection of extruded profiles, shapes and forms. We also maintain extensive tooling capabilities to undertake large volume production parts with short lead times. Our tooling capabilities is what separate us from other extruders.

- Polymer extrusion is a manufacturing process that produces long parts with consistent cross-section.

- Profiles, multiple hollow shapes, rods, pipes, sheets, and films are some of the common products that are produced using polymer extrusion.

- The polymers used in our extrusion processes are generally made from rubber and plastics along with many custom special performance blended alloys.

- Our polymer extrusion processes are versatile and equipped to create parts in complex shapes, with varying thicknesses, hardness, colors and textures.

- Extruded parts exhibit stable structural integrity, uniform density and durability.

Material

PVC • Nylon 66 • RPVC • Butyl Rubber • FPVC • EDPM (dense and sponge rubber) • PP • PE • TPU • Fluoroelastomer/FKM Neoprene (dense and sponge rubber) • Polypropylene • ABS • Nitrile Rubber • ETFE • Polyisoprene • PVC • Dual Durometer • Silicone (dense and sponge rubber) • Acrylic • TPO • Styrene • HIPS • Butyrate • TPR • Nylon • Santoprene • TPE • Thermoplastic Polyester Elastomer • Ultra High Molecular Weight • PLA • Hytrel • EVA • Noryl • HDPE • UHMW Polyethylene • Polyurethane • SBR • Neoprene • Thermoprene • Fluoroelastomers • Silicone • Rubber • Plastic • Vinyl • Acetal • Delrin

Industries who use Extruded Polymers include:

- Point of Purchase

- Architectural

- Marine

- Lawn and Garden

- Automotive Aftermarket

- Appliances

- Furniture

- Construction

- Transportation

- Panels

- Building Envelope

- Road Construction

- Signage

- Display

- Fenestration

- Vinyl Fences

- Vinyl Packaging

- PVC Poles

- Clear PVC Strips

- PVC Strips